Wet Cleaning: For a more thorough clean, proceed with wet cleaning.This step minimizes the risk of scratching the record during wet cleaning. Gently brush the surface in a circular motion, starting from the outer edge and working towards the center. Use a carbon fiber or anti-static brush specially designed for record cleaning. Dry Cleaning: Begin by dry cleaning the vinyl record to remove loose dust and debris.Hold the record by its edges or label, minimizing contact with the grooves. Precautions: Handle with Care: Always handle vinyl records with caution to avoid fingerprints, oils, and dirt from transferring onto the playing surface.Record cleaning machine (optional, but highly recommended).Microfiber cleaning cloth or dedicated record cleaning brush.

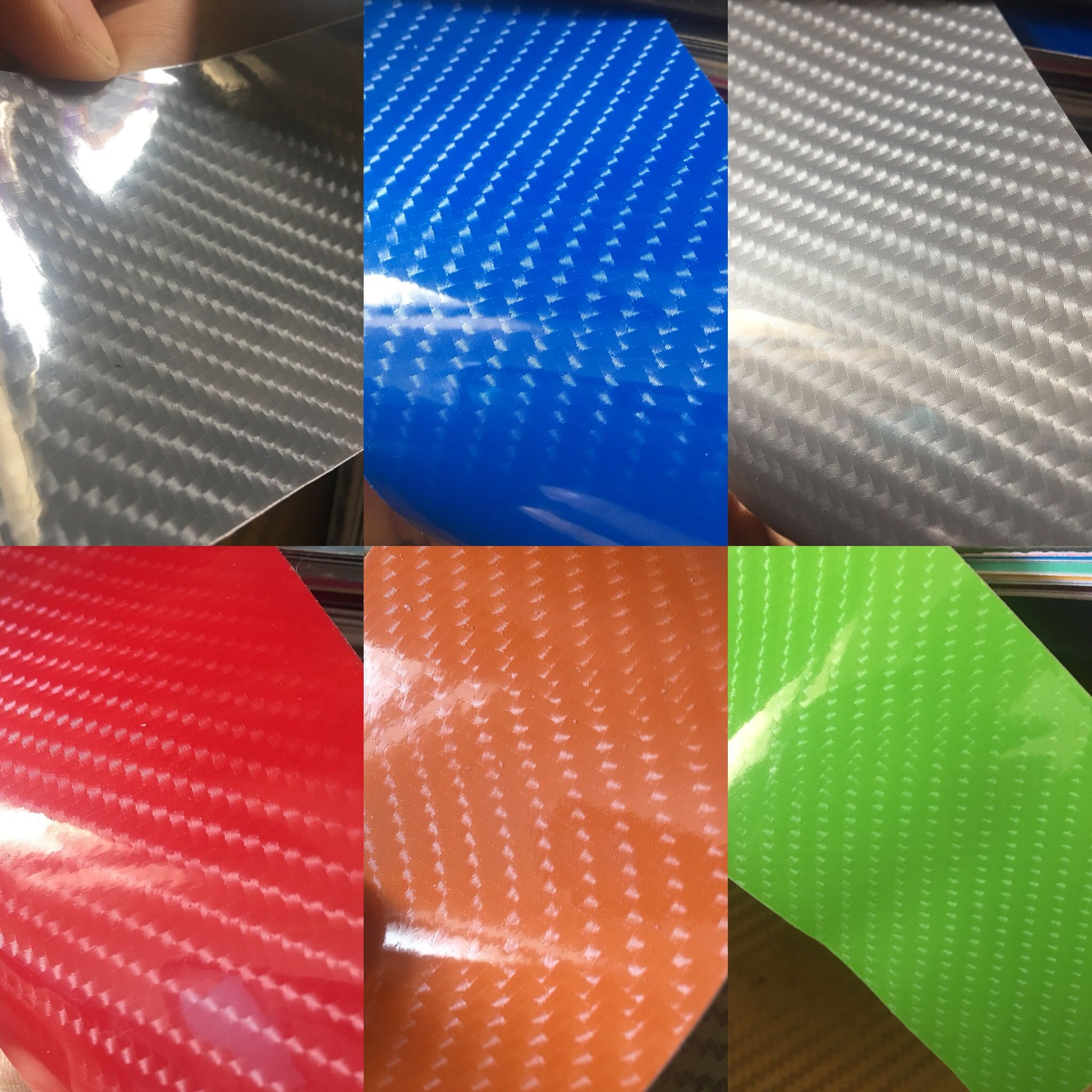

TechShop is a membership-based workshop that provides members with access to tools and equipment, instruction, and a community of creative and supportive people so they can build the things they have always wanted to make. Check out their website,, if you're interested. I found everything I needed except the vinyl at the TechShop in Menlo Park, CA. Heat gun (hair dryer will work, but an adjustable heat gun is preferred) Plastic card for smoothing out bubbles (an old credit card will work, but it helps to smooth the edges a little) CA-421 corresponds to the traditional black-and-grey-ish carbon fiber look)

3M Di-Noc CA-421 carbon fiber vinyl (there are other styles available, including different shades of carbon fiber. I have done this on a number of cars, and the technique can be applied to just about anything, some people even wrap their hood or trunk lid with this stuff.

#Carbon fiber vinyl how to#

These are instructions for how to wrap your automotive interior with carbon fiber vinyl.

0 kommentar(er)

0 kommentar(er)